In the global market, supply chain efficiency is very important for business success. Supply chains management have grown increasingly complex, facing challenges such as fluctuating demand, inventory shortages and unpredictable delivery times. Machine learning (ML) has emerged as a powerful tool to help businesses optimize their supply chains, reduce operational costs and enhance customer satisfaction.

In this post, we shall discuss the role of machine learning in supply chain management through applications like demand forecasting, inventory optimization and route planning, supported by real world examples from companies like Amazon and Walmart.

What is Role of Machine Learning in Supply Chain Management?

Machine learning uses algorithms and data analytics to recognize patterns, make predictions and automate decision making processes. When applied to supply chain management, ML can:

– Predict future demand accurately

– Automate inventory management to minimize stock-outs or overstocking

– Optimize routes for faster delivery

– Improve overall efficiency by streamlining processes

Let’s discuss deeper into the key areas where machine learning is transforming supply chain management.

1. Demand Forecasting: Predicting What Customers Want

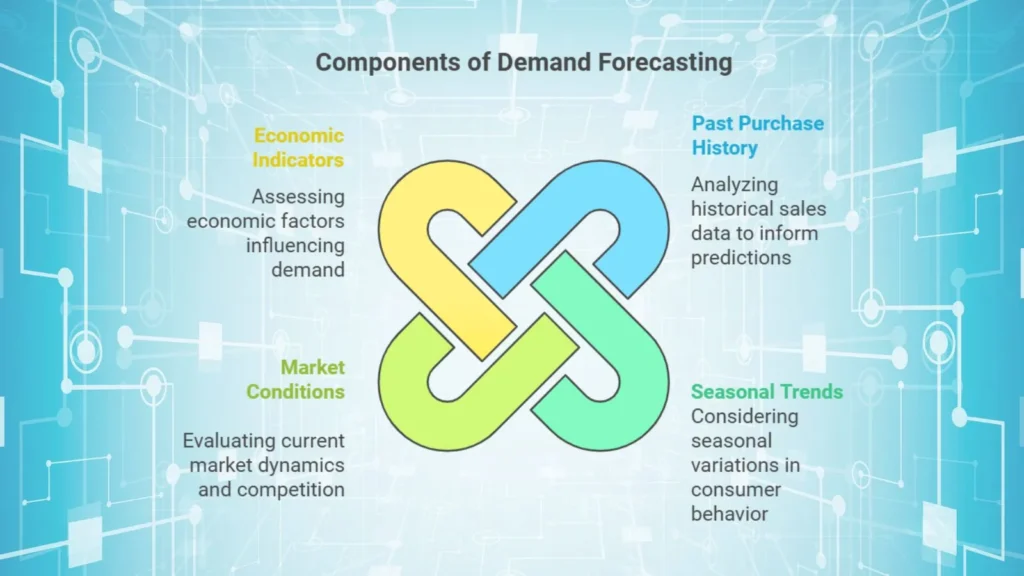

Demand forecasting is very important in supply chain management because it helps businesses to anticipate customer demand, which allows them to adjust production, inventory and logistics accordingly. Traditional forecasting methods relied on historical data and basic statistical models. Machine learning, however, uses sophisticated algorithms that consider multiple variables, including:

– Past purchase history

– Seasonal trends

– Market conditions

– Economic indicators

Machine learning algorithms can continually update and improve their forecasts as new data becomes available, to make predictions more accurate over time.

Real World Example: Amazon’s Demand Forecasting

Amazon’s demand forecasting system utilizes machine learning to predict which products customers are likely to purchase. By accurately forecasting demand, Amazon manages its inventory efficiently, to ensure items are available when needed. This allows Amazon to reduce holding costs and avoid stock-outs, which ultimately leads to faster delivery times for customers.

2. Inventory Management: Balancing Stock Levels

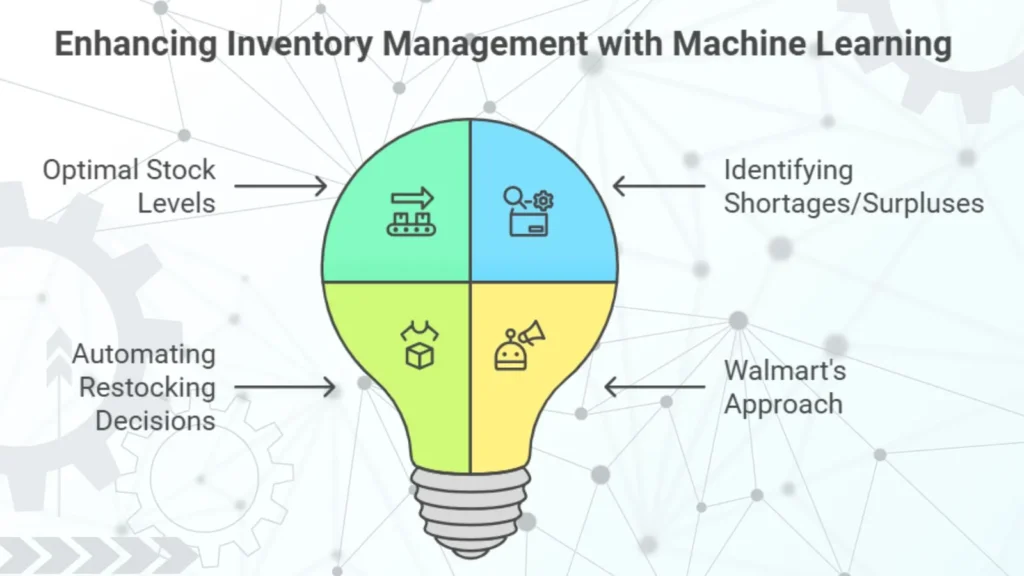

Effective inventory management ensures that businesses have the right products in the right quantities at the right time. Overstocking and understocking are costly mistakes that can harm customer satisfaction and cash flow. Machine learning models analyze data across supply chain touchpoints to help businesses:

– To determine optimal stock levels

– To identify potential inventory shortages or surpluses

– To automate restocking decisions

Real World Example: Walmart’s Inventory Optimization

Walmart uses machine learning to manage its inventory across thousands of stores. The company’s ML driven systems analyze purchasing patterns, weather conditions and even local events to predict demand fluctuations. This enables Walmart to adjust its inventory dynamically, by ensuring shelves are stocked with high demand products while reducing excess inventory.

3. Route Optimization: Streamlining Delivery Logistics

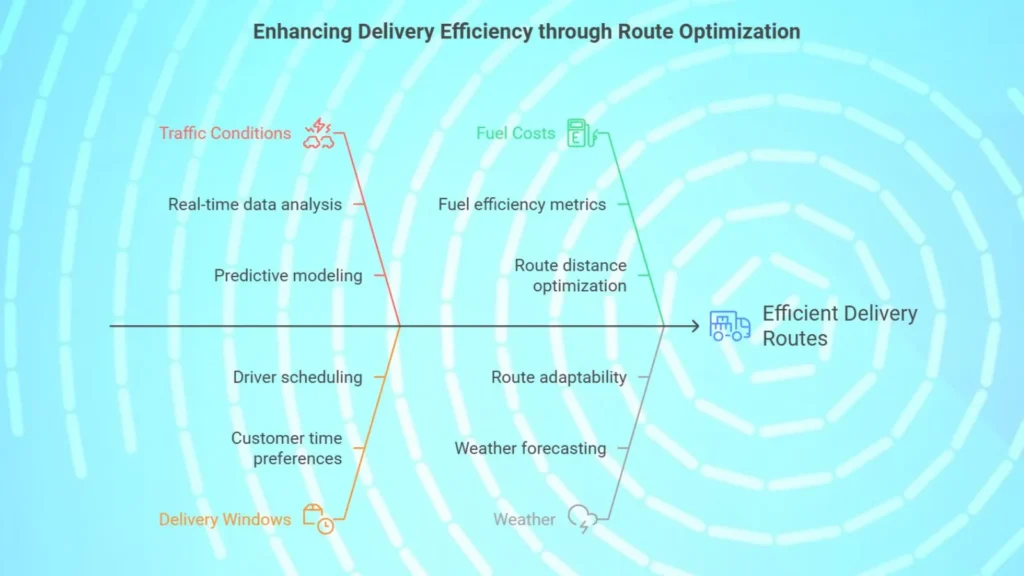

Route optimization is essential to reduce transportation costs and to improve delivery times. Machine learning can enhance route planning by analyzing multiple factors like traffic conditions, delivery windows, fuel costs and many more. ML algorithms can generate optimal routes that adjust in real time based on changing conditions, such as traffic congestion or weather.

Real World Example: UPS’s ORION System

UPS uses an advanced machine learning system called ORION (On-Road Integrated Optimization and Navigation) to optimize delivery routes. ORION uses package data, GPS tracking and machine learning to calculate the most efficient routes. It’s estimated that ORION saves UPS around 10 million gallons of fuel annually by reducing delivery times and miles traveled.

4. Enhancing Customer Satisfaction Through Predictive Analytics

Customer satisfaction is a key metric for supply chain performance. Machine learning improves customer satisfaction by providing greater transparency, faster delivery times and more reliable service. By analyzing customer behavior and preferences, ML can predict customer needs, to offer proactive service.

Example: Real Time Order Tracking by FedEx

FedEx uses machine learning to enhance its tracking system, which provides real time updates and delivery time predictions. Customers receive notifications if there’s a delay or change, which enhances trust and satisfaction by keeping customers informed throughout the shipping process.

5. Predictive Maintenance: Reducing Downtime and Repair Costs

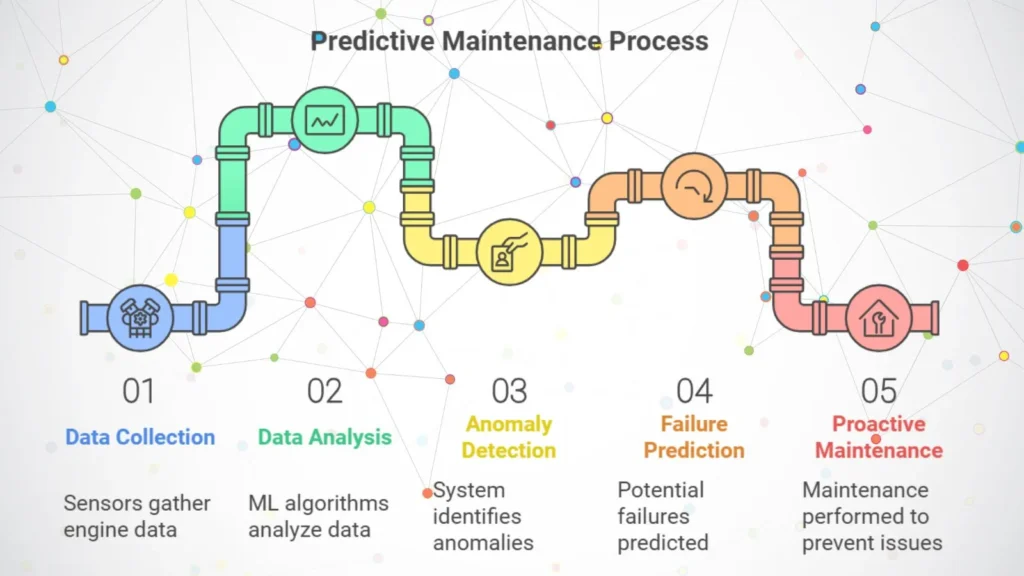

Predictive maintenance uses machine learning to monitor equipment health and predict failures before they happen. This approach is particularly useful in manufacturing, where machine downtime can lead to significant production delays and increased costs. ML algorithms analyze historical maintenance data, sensor data and environmental conditions to predict when maintenance should be performed.

Real-World Example: Rolls-Royce and Predictive Maintenance

Rolls-Royce employs machine learning to monitor the performance of its airplane engines. Sensors installed on the engines collect data on temperature, pressure and vibration. The data is analyzed to detect anomalies and predict potential failures, which enables them to do proactive maintenance and reduce unplanned downtime.

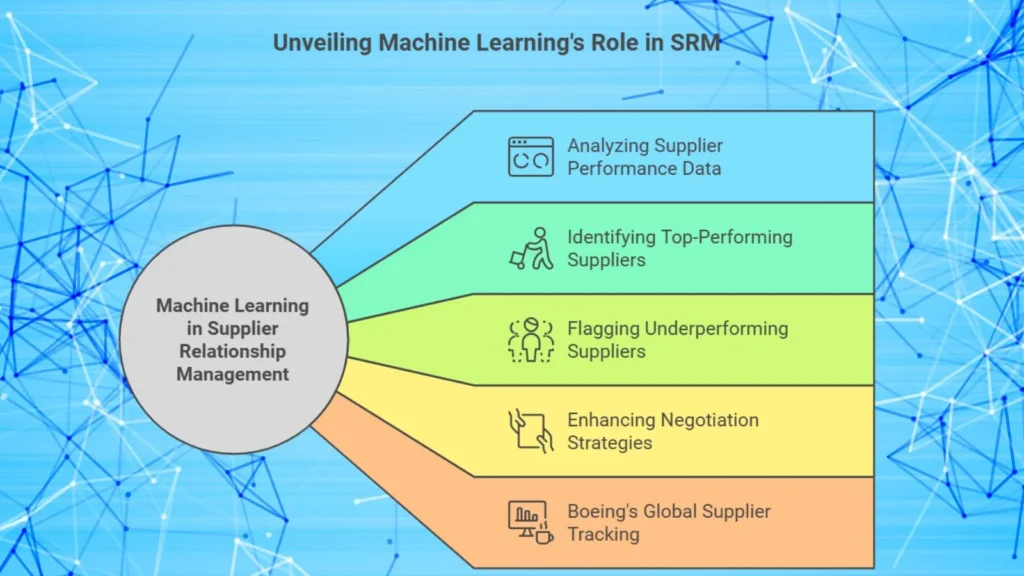

6. Supplier Relationship Management (SRM)

Machine learning enhances supplier relationship management by analyzing supplier performance data, such as delivery times, quality rates and cost efficiency. ML can identify top performing suppliers and pin-point underperforming ones, which helps businesses to choose better supplier and negotiate better contracts based on this data.

Example: Boeing’s Supplier Management System

Boeing uses machine learning to track and evaluate supplier performance globally. By analyzing data from various suppliers, Boeing identifies trends, anticipates delays and adjusts sourcing strategies to maintain production efficiency and quality.

Key Benefits of Machine Learning in Supply Chain Management

Machine learning provides several significant benefits for supply chain management:

1. Increased Efficiency:

ML automates repetitive tasks, to free up human resources for higher level strategic tasks.

2. Cost Reduction:

By optimizing inventory, routes and maintenance schedules, businesses can reduce operational costs.

3. Enhanced Customer Satisfaction:

Accurate demand forecasting and efficient inventory management ensure that products are available when customers need them.

4. Improved Flexibility:

ML models adjust to changing conditions, which makes supply chains more adaptable.

5. Data-Driven Decision Making:

Machine learning provides insights based on data, which enables them to take more accurate and informed decisions.

6. Risk Mitigation:

Early identification of supplier risks and potential equipment failures reduce unexpected disruptions.

7. Sustainability:

Optimized routes and predictive maintenance reduce fuel consumption and carbon emissions, contributing to sustainable operations.

Challenges of Implementing Machine Learning in Supply Chain

Despite its advantages, there are challenges associated with using machine learning in supply chain management:

– Data Quality:

ML models rely on high quality data. Inconsistent or inaccurate data can lead to poor predictions.

– High Implementation Costs:

Setting up ML systems, hiring specialists and maintaining the infrastructure can be costly.

– Integration with Legacy Systems:

Many businesses use older software systems that may not be compatible with modern ML models.

– Privacy and Security:

Handling large volumes of data raises concerns about data security and compliance with privacy regulations.

Future Trends in Supply Chain Management

As technology advances, machine learning is expected to play an even larger role in supply chain management. Here are some trends to watch for:

1. AI Driven Supply Chain Digital Twins:

Digital twins are virtual models of physical assets, processes, or systems. With AI and ML, digital twins in supply chain management can help to simulate scenarios and optimize operations in real time. Companies will have real time visibility into every aspect of the supply chain, from supplier locations to delivery times.

2. Autonomous Supply Chains:

Future supply chains may become increasingly autonomous, with robots and AI systems to handle warehousing, transportation and logistics with minimal human intervention.

3. Sustainability Optimization:

Machine learning can analyze carbon footprints and optimize resource usage, which contributes to sustainable supply chain practices.

Conclusion

Machine learning has revolutionized supply chain management by improving efficiency, reducing costs and enhancing customer satisfaction. Through applications in demand forecasting, inventory management and route optimization, companies like Amazon, Walmart and UPS are using Machine Learning to streamline their supply chains.

As ML technology continues to evolve, we can expect even more innovative solutions that will further optimize supply chains, reduce environmental impact and help businesses adapt to changing demands.

By embracing machine learning, businesses can enhance their supply chain performance and also drive long term growth and get competitive edge in global market.

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

Your point of view caught my eye and was very interesting. Thanks.